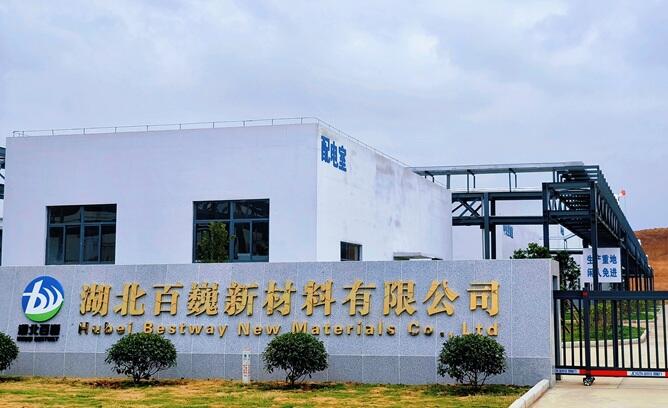

HUBEI BESTWAY TECHNOLOGY CO.,LTD

A Hubei Yaojiagang Kémiai Parkban, Yichangban található 40 012 négyzetméteres termelőbázisunk, amely éves 100 000 tonnás kapacitással rendelkezik, bemutatja gyártási erősségünket; nemzeti magas technológiai vállalatként, 14 szabadalmal és ISO 9001, SGS és REACH tanúsítvánnyal, összekapcsoljuk a legmodernebb innovációkat a szigorú minőségbiztosítással, országos szabványoknak megfelelő haladó gépeszkedzzel teremtve versenyképes árukért magas minőségű termékeket. Rendkívüli készletünk gyors szállítást biztosít különböző specifikációk között, miközben szakértő csapatunk elkötelezett a legjobb szolgáltatás mellett; termékeink már több mint 30 országba érkeztek világszerte, és reméljük hamarosan partnereink lesznek, hogy közös növekedést érjünk el, és hosszútávú, nyereségességű kapcsolatot építsünk fel a világi színpadon.

ÁRJEGYZÉK KÉRÉSE