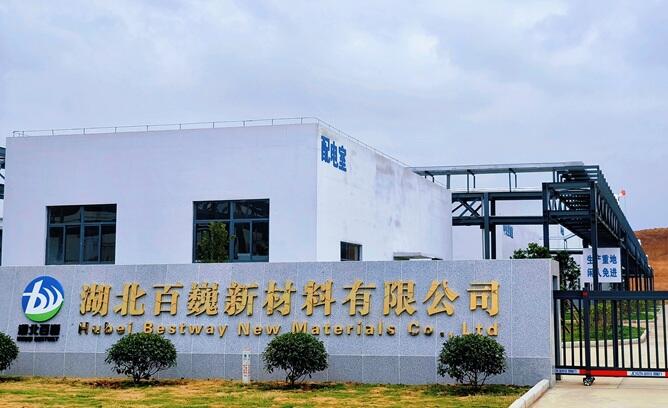

HUBEI BESTWAY TECHNOLOGY CO.,LTD

Gelegen in de Yaojiagang Chemiepark van Yichang, Hubei, onze productiebasis van 40.012 vierkante meter, met een jaarlijkse capaciteit van 100.000 ton, toont onze productiemacht; als een nationaal hightechbedrijf met 14 patenten en gecertificeerd volgens ISO 9001, SGS en REACH, combineren we snijrandinnovatie met strikte kwaliteitscontrole, waarbij gebruik wordt gemaakt van geavanceerde machinerie die voldoet aan nationale normen om hoogwaardige producten tegen scherpe prijzen te produceren. Met een goed gevulde voorraad die snelle levering garandeert over diverse specificaties en een toegewijd team dat zich richt op uitstekende service, hebben onze producten meer dan 30 landen wereldwijd bereikt, en we zijn benieuwd om samen te werken om wederzijds groei te realiseren en een duurzame, win-winsituatie op het wereldtoneel op te bouwen.

VRAGEN OM EEN OFFERTE