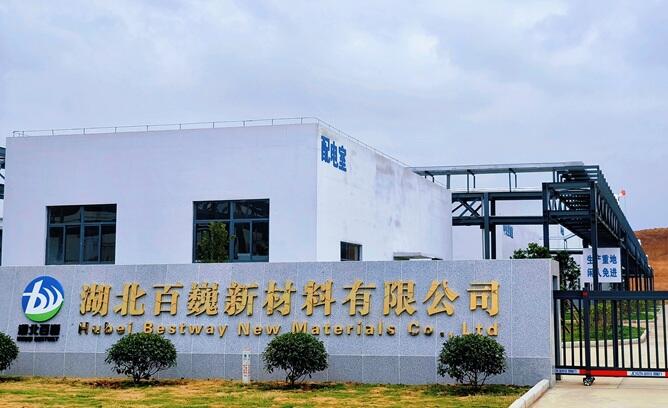

HUBEI BESTWAY TECHNOLOGY CO.,LTD

Smještena u kemikalijama Yaojiagang u Yichangu, Hubei, naša proizvodna baza od 40.012 kvadratnih metara, sa godišnjom kapacitetom od 100.000 tona, prikazuje našu proizvodnu snagu; kao nacionalno visokotehnološko preduzeće koje poseduje 14 patenta i je sertifikovano prema ISO 9001, SGS i REACH-u, spajamo inovacije na vrhu tehnologije sa strogom kontrolom kvaliteta, koristeći napredne mašine u skladu sa nacionalnim standardima kako bismo izradili kvalitetne proizvode po konkurentnim cenama. Sa dobro opremljenim zalihama koje osiguravaju brzu dostavu u različitim specifikacijama i posvećenim timom koji se trudi da pruža najbolju uslugu, naši proizvodi su stigli u preko 30 zemalja širom sveta, a volimo da se partnerisemo s vama kako bismo ostvarili zajednički rast i izgradili trajnu, dobijedničku vezu na globalnoj sceni.

Zatražite ponudu